Chocfast Black

Specially formulated 100% solids, inert filled casting compound developed for use as a chocking material.

Description

Chockfast Black is a specifically formulated 100% solids, inert filled casting compound developed for use as a chocking material. It is a cost-effective method of maintaining permanent precise alignment of critical equipment. It will withstand severe environments involving high physical and thermal shock.

This unique product is used under gas and diesel engines, compressors, generators, turbines, motors, pumps and various other types of equipment.

Chockfast Black is ideal for use under these hot running reciprocating and rotating machines because of its excellent resistance to creep and fatigue at high operating temperatures. It is non-shrinking and has a very high impact and compressive strength. Resin chocks made with Chockfast Black reduce possible bearing or crankshaft damage because they

(1) minimise heat build-up on foundations,

(2) assure precise and unsurpassed contact with bedplates, and

(3) provide a high coefficient of friction to help hold engines down tight.

The excellent flowability of Chockfast Black allows it to fill voids in the chock area and conform to all surface irregularities

Chockfast Black was designed to be a thick pour liquid chocking material. Achock depth of 2″ (50mm) is standard; however, thinner or thicker pours can be made satisfactorily. The 2″ (50mm) chock lation wh elevates equipment above the underlying foundation, which allows a free flow of air thereby reducing nossible foundation buming prablame possible foundation humping problems. Contot ITW Contact ITW Polymers and Fluids for information regarding pours less than 1-1/4″ (32mm) in thickness or greater than 2-1/2″ (62mm) in thickness.

The information contained in this Technical Bulletin is as up to date and correct as possible as at the time of issue. The data provided should be used as a guide only as the performance of the product will vary depending on differing operating conditions and application methods. The sale of any product described in this Technical Bulletin will be in accordance with ITW Polymers & Fluids Conditions Of Sale, a copy of which is available onon request. To the extent permitted by law, ITW Polymers & Fluids excludes all other warranties in relation to this product.

APPLICATION INSTRUCTIONS

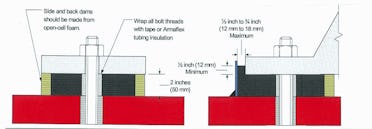

Construct a chock mould around one or more anchor bolts using open cell foam damming material on three sides. Wrap the shank of the anchor bolt with tape, cover with foam pipe insulation or coat with non-melt grease to prevent the CHOCKFAST from sticking to it and to seal the bolt hole. Place a metal the CHOCKEAST from sticking to it and to seal the bolt hole Place a me tont ano sea dam 1/2″ to 3 dam 1/2″ to 34″ (12mm to 18mm) from the mounting pad and seal with caulk. Spray the inside of the mold and front metal dam with Release Agent. Mix and pour the epoxy as directed.

Product specification sheet

Chocfast Black product specification sheet opens in a new windowManufacturer

Epirez