A Homeowner’s Guide to Roof Waterproofing in Australia

Australia’s climate is tough on roofs. Intense UV, severe storms, and massive temperature swings break down even quality materials.

40% of Australian homeowners experience water leaks during heavy rain, and most homeowners ignore their roof until water actually starts leaking inside.

By then, you’re looking at expensive repairs.

Before doing anything, figure out when waterproofing is needed, which systems work for your roof, and whether this is a DIY job or one for the professionals.

Signs Your Roof Needs Waterproofing

Water stains on ceilings are obvious. They appear as brown or yellow marks that show up after rain, paint bubbles, plaster cracks, and damp patches that come and go.

Damaged tiles let water straight through to the roof structure. Look for cracked terracotta, broken concrete tiles, or loose metal sheets. Where membranes have been installed, check for lifting, cracking, or UV degradation.

Noticed moss or algae? That means moisture is hanging around. The growth traps water against your roof, which is worse in coastal areas.

The age of your roof is also a determining factor. Most waterproofing lasts 10-15 years, depending on what you’ve got and how much sun it gets. If yours is getting close to that, get it checked even if it looks fine.

Australia’s Unique Climate Challenges

Australia’s climate is brutal on roofs. UV radiation here is intense, and it breaks down membranes and coatings over time, making them brittle and cracked. And the daily temperature changes expand and contract roofing materials constantly, putting stress on joints and penetrations.

Storm seasons vary by region. Northern Australia gets monsoons with sustained heavy rain, while Southern regions get intense storm cells that dump massive amounts of water fast. Both test your waterproofing.

If you live near the coast, salt in the air accelerates corrosion on metal roofing and degrades some waterproofing products. Coastal properties need more frequent maintenance and products designed for marine environments.

Temperature extremes affect all Australian roofs. Metal roofing changes in size significantly between summer heat and winter cold. Your waterproofing has to handle this movement without cracking or peeling off.

Types of Waterproofing Systems

Liquid Applied Membranes

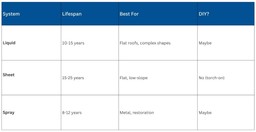

Liquid waterproofing products include acrylic, polyurethane, and bitumen-based options. They cure into a seamless barrier with no joins or weak points. These work well on flat roofs and complex shapes where sheet membranes would need extensive cutting and joining.

What’s good: No seams, flexible enough to handle substrate movement, UV resistant if you pick the right formulation. Works on irregular surfaces.

What’s not: You need decent technique to get proper thickness. The weather also matters, as rain during curing will wreck it. Ensure the temperature is within the product’s specifications.

How long it lasts: 10-15 years if you apply it properly and pick quality products.

Sheet Membranes

Sheet waterproofing comes as torch-on, self-adhesive, or mechanically fastened. These pre-made membranes deliver consistent thickness and have a proven track record on flat and low-slope roofs.

What’s good: Tough, reliable, same thickness throughout. Harder to puncture than liquid systems.

What’s not: Seams fail if not done right. Needs a skilled professional with proper gear.

How long it lasts: 15-25 years with quality products and proper installation.

Spray-On Coatings

Spray-applied elastomeric and silicone coatings offer fast application for roof restoration. These work well over existing waterproofing or metal roofs, with many providing heat reflection.

What’s good: Quick to apply, reduces roof temperature, and can go over most surfaces. Extends the life of old waterproofing without full replacement.

What’s not: Need multiple coats for proper thickness. You need to ensure you pay attention to surface preparation; otherwise, it won’t stick. It is thinner than other systems, so it might not last as long.

How long it lasts: 8-12 years.

Quick Comparison

Different Roof Types

Tile Roofing

Tile roofs (terracotta and concrete) need under-tile sarking or over-tile coatings. Under-tile is better, but requires tile removal. Point and reseal the ridge capping, as that’s where water typically gets in.

Badly degraded or broken tiles need replacing—don’t try coating over damage. Intact aged tiles can be restored with coatings.

Metal Roofing

Metal roofs (Colorbond and Zincalume) are waterproof. Leaks show up at seams, screws, and damaged spots. Fastener washers break down under UV, so check and reseal them regularly. Coatings extend roof life, but treat rust first, as coating over it achieves nothing.

Flat and Low-Sloped Roofing

Flat and low-slope roofs are the hardest. You need to fix the drainage before waterproofing, as standing water kills membranes. Torch-on sheet membranes and thick liquid systems work best. Edge details and penetrations need extra attention because water sits there.

Other Types of Roofing Materials

Some roof types have specific requirements. Slate roofs don’t need membrane waterproofing—just replace damaged slates and maintain flashing. Asbestos cement roofs require professional assessment before any work begins. Green roofs need specialised waterproofing systems that resist root penetration.

DIY or Professional?

When DIY Works

You might manage DIY if you’ve got decent skills, you’re doing small repairs or coatings, and your roof is accessible and low-pitch.

Be honest. Can you work at heights safely? Will you follow the technical specifications, mixing ratios, coverage rates, and temperature requirements? Most waterproofing needs multiple coats in the right weather with proper drying time between. A professional crew finishes in days what may take you weeks of weekends.

Budget drives most DIY decisions. But waterproofing that isn’t done correctly can cost more in water damage than a professional installation would’ve.

When to Call Someone

Get a professional for steep or complex roofs, structural problems, major damage, or torch-on membranes. Propane torches are dangerous if you don’t know what you’re doing.

Building codes and warranties often require a professional installation. Many product warranties need certified installers, as undertaking DIY work voids them. And working at heights is one of the most dangerous home maintenance jobs. Don’t risk it if you’re not confident.

DIY Application Basics

Safety And Preparation

You will need a proper safety harness, non-slip boots, and respiratory protection if using solvent products. Check the weather, as you need several dry days with temperatures within product specs. Pressure wash off dirt and growth, fix all damage and follow the manufacturer’s guidelines on whether you need to prime.

Application

Start at the highest point, and work down. Apply the first coat at the coverage rate on the tin. Let it dry properly between coats (usually several hours to overnight). The second coat goes perpendicular to the first for full coverage.

Critical spots:

- Flashing around chimneys and vents—build up extra material in corners

- Ridge capping and valleys—consider reinforcement fabric

- Roof-to-wall junctions—run membrane up the wall per specs

- Every penetration and fastener needs individual sealing

- Edge details need proper termination, or water wicks back underneath

Curing: Most products need 24-48 hours minimum before rain. Keep people and pets off during curing.

Choosing the Right Waterproofing Products

Key Selection Criteria

Match products to your climate. The tropical north needs products that handle moisture and UV, the temperate south gets big temperature swings, while the arid inland has extreme heat.

You also need to check substrate compatibility. Not everything works on everything. Using the wrong product leads to adhesion failure or chemical reactions.

Some products degrade fast under intense sun, others last for years, so check the UV stability.

The membrane has to handle expansion and contraction without cracking. Metal roofs need flexible products that can handle significant movement.

Low-VOC products are healthier but might have tighter temperature windows for application. AS/NZS 4200 series compliance means the product meets Australian Standards.

Product Categories

Quality waterproofing supplies come in three main categories suited to different applications.

Cementitious waterproofing is rigid or semi rigid and good for concrete and masonry, such as water tanks and basements. Works where substrate movement is minimal.

Liquid waterproofing comes in acrylic, polyurethane, and bitumen-based options. Each has different properties. Pick based on your substrate, exposure, and the level of flexibility you need.

Sheet waterproofing is tough with proven long-term performance. Consistent thickness throughout. Generally, more durable than liquid systems.

Reading Specs

Technical data sheets have the information you need, including application methods, coverage rates, curing times, and performance specifications.

Coverage rates tell you how much product you need. Don’t skimp on trying to save money. Proper thickness is essential. Calculate your roof area, including details (add 10% for waste).

Temperature windows will tell you when you can apply the product. Australian extremes might limit your timing, so plan around suitable conditions.

Some products need hours between coats, others need overnight. Just remember that “dry to the touch” isn’t “fully cured”.

Common Mistakes

Skipping surface preparation causes most failures. Poor adhesion leads to delamination and water penetration. Clean thoroughly and address all damage before applying waterproofing. This takes time, but it’s important.

Ignoring weather conditions during application compromises results. Applying outside temperature and humidity requirements, or right before rain, is pointless. You’ll just have to do it again.

Insufficient product coverage creates thin spots and voids. Plus, water finds these weak points. Apply at manufacturer-recommended rates. Don’t try to stretch coverage to save money—you’ll pay more for fixing failures.

Neglecting critical details at flashings, penetrations, and termination points causes leaks. These areas need extra attention and proper technique. Most roof leaks happen at details, not in the main field.

Using incompatible products with your substrate or mixing different coating systems can result in adhesion failure or chemical reactions. Stick with one manufacturer’s system. Don’t mix and match.

Maintenance

Check quarterly and after storms. Get annual professional inspections. Look for cracks, blistering, or deteriorating coating.

Regular tasks:

- Clean gutters and remove debris

- Trim overhanging branches

- Touch up minor cracks

- Reseal fasteners and joints

- Clean moss and algae, especially in shade or coastal areas

When to recoat or replace: Widespread cracking, multiple leaks, or coating near end of life means maintenance isn’t enough. Sheet membranes last 15-25 years, liquid systems 10-15 years, spray coatings 8-12 years.

What It Costs

What Affects Cost

Costs vary based on access difficulty, roof pitch, need for repairs first, product quality, and location. Sydney and coastal areas cost more than regional areas.

Is It Worth It?

Water damage from roof leaks costs $5,000-$20,000+ in ceiling, wall, and structural repairs. Waterproofing costs a fraction of that. Plus, it protects your property value.

Standards and Regulations

AS/NZS 4200 series covers the basics for waterproofing materials and how they’re applied. But your state might have extra requirements. Check with your council about permits before you start, as major roof work sometimes needs approval. If you’re changing the structure or working on a heritage place, this is a definite.

Licensed contractors know about compliance. Most states require specific waterproofing licenses, not just general building licenses. They’ll give you certificates showing the work meets standards. Keep them as your insurer might want proof down the track.

Taking Action on Roof Protection

Waterproofing stops the weather from damaging your roof, or at least slows it down. It’s cheaper than fixing water damage through your ceiling and walls. Figure out which system works for your roof type and where you live. And be realistic about your skills. Some jobs are DIY-friendly, while others aren’t.

Checking your roof regularly means you catch problems early, when they’re cheap to fix. If you leave them, you’ll pay. Good waterproofing isn’t cheap upfront, but it saves you money long-term.

Common Questions

How long does roof waterproofing last in Australia?

It depends on the system and where you live. Sheet membranes last 15-25 years, liquid membranes 10-15 years, spray coatings 8-12 years. UV, temperature extremes, and coastal conditions cut these timeframes. Of course, undertaking regular inspections and maintenance will extend the life.

What’s the difference between waterproofing and sealing?

Waterproofing creates a continuous barrier that stops all water. Sealing fills gaps and cracks to reduce water entry. Waterproofing systems are membranes or coatings designed for complete protection. Sealing addresses specific leak points but doesn’t cover everything.

Can you waterproof a roof in winter?

Yes, but check product temperature requirements. Most need a minimum of 10-15°C during application and curing. Winter in many Australian regions is fine, though southern areas might struggle. Pick mild days and watch rain forecasts.

Is roof waterproofing covered by insurance?

Generally no. Preventative waterproofing is maintenance. But if storm or fire damages your roof, repairs might include waterproofing. Check your policy, and keep documentation of roof maintenance for claims.

How often should I waterproof my roof?

Inspect annually, recoat or replace every 10-25 years, depending on system type. Harsh coastal environments or extreme UV might need more frequent attention. Regular maintenance and quick repairs extend the time between full waterproofing jobs.

What’s best for Australian conditions?

Depends on your location and roof type. Coastal areas need UV-resistant, salt-tolerant products. Northern tropical regions need products that handle constant moisture. Metal roofs suit flexible coatings. Flat roofs perform best with sheet membranes or thick liquid systems.

- Date

- 28/12/2025