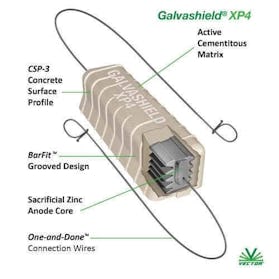

Galvashield XP Anodes

The Galvashield® XP range of embedded galvanic anodes

are used to mitigate ring anode corrosion when repairing

reinforced concrete structures.

Description

The Galvashield® XP range of embedded galvanic anodes

are used to mitigate ring anode corrosion when repairing

reinforced concrete structures. Designed for optimum

performance and ease of installation, the alkali-activated (Type

1A) Anodes are comprised of high-purity zinc cast around a

steel tie wire with an enhanced, formulated cement-based

mortar with an internal pH of 14 or greater that keeps the zinc

active over the life of the anode. The Galvashield® XP range

of anodes utilize the contractor-friendly One-and-Done™

single-wire connection. Once installed, the zinc anode corrodes

to provide galvanic corrosion prevention or corrosion control

to adjacent reinforcing steel.

Applications

- Mitigates ring anode formation (halo effect) in the patch repair applications

- Bridge widening and other structure modifications

- Slab replacements, expansion joint repairs and other interfaces between new and existing concrete

- Repair of prestressed and post-tensioned concrete

- Chloride-contaminated or carbonated concrete

- Repair of structures with epoxy-coated rebar

- Extends the life of concrete repairs

- Extends the life of joint repairs

Advantages

- Proven technology – Galvashield® is the original

embedded galvanic anode with an extensive 20-year

track record. - Independent testing – indicates concrete repair service

life can be extended by more than 400%. - Type 1A anode – alkali-activated to maintain activity of

zinc; meets building code requirements that prohibit

intentionally added constituents that are corrosive to

reinforcement within the repair area. - One-and-Done™ connection innovative single wire

connection can be installed up to 2x faster than the

traditional two-wire connection, saving 50% on installation

labour cost. - Cast zinc core – provides high anode utilisation and a

secure long-term connection between the zinc and the

integral lead wire. - BarFit™ design – grooved edges on Galvashield® XP2

and XP4 anodes assist with secure anode placement. - Steel connection wires – Provides dependable steel-to-steel contact with no intermediate materials such as

galvanizing that may compromise the long-term electrical

connection. - Economical – provides localized protection where it is

needed the most, at the interface between the repair and

the remaining contaminated concrete. - Versatile – can be used for both conventionally reinforced

and prestressed or post-tensioned concrete. - Low maintenance – requires no external power source or

system monitoring. - Long lasting – 10 to 30-year anode service life* reduces

the need for future repairs. - CSP-3 Surface Profile – raised ridges provide increased

surface profile to promote mechanical bond with repair

mortars and concrete.

*As with all galvanic protection systems, service life and

performance is dependent upon a number of factors including

reinforcing steel density, concrete conductivity, chloride

concentration, humidity and anode spacing.

Product specification sheet

Galvashield XP Anodes product specification sheet opens in a new windowManufacturer

Parchem Construction Supplies